Black Smoke Engine Exhaust System

Check for Diagnostic Trouble Codes

Black smoke is caused by too much fuel being processed inside your car's engine and then released from the tailpipe of your car. Malfunctions in fuel delivery or internal system leaks will cause black smoke to come from the tailpipe. Before fuel injection became available in automobiles in the mid 1980's, the carburetor was the main fuel and air mixer in most vehicles. A carburetor was a simple device that supplied the engine with proper fuel to air mixtures. Carburetors performed two operations 1. meter air flow 2. deliver the correct amount of fuel to air mixture. This mix could be kept even during the wide range of extra factors associated with an engine such as high temperature, cold starting, hot starting, idling and acceleration.

The primary difference between a carburetor and a fuel injection system is that the fuel injection system atomizes fuel by pushing it through a small nozzle under pressure, while a carburetor utilizes vacuum created by air flow into the intake manifold. Airflow in an injection engine is controlled by the throttle body; fuel is distributed directly in each cylinder. This creates better fuel control, lower emissions and faster acceleration. The process of measuring the amount of fuel a fuel injector is dispersing is determined by the PCM (powertrain control module). The fuel injection system has several parts: the mass airflow sensor or map sensor, throttle body, throttle position sensor, idle control valve, fuel pump, fuel pressure regulator, fuel lines, and oxygen sensors.

Cause of Black Smoke

Black smoke is caused when the mix of fuel and air becomes un-balanced. Normal mixture is 14.5 parts air to1 part fuel. When the fuel to air mixtures change because of a malfunction the mixture can go as high as 14.5 to 2 or 3, two to three times the proper amount. The black smoke is the excess fuel generated from the rich mixture and can be cause by one of the following:

- Plugged Air Filter

- Shorted or stuck fuel injector

- Failed fuel pressure regulator

- Vacuum leak

- Shorted Computer Sensor

Troubleshooting Black Smoke for Exhaust

Testing for a Blown Fuel Pressure Regulator Diaphragm - A fuel pressure pressure by using a diaphragm/spring combination in conjunction with intake manifold vacuum. When the fuel pressure regulator diaphragm ruptures it allows raw fuel into the vacuum feed line and then into the intake system of the engine. This condition creates a rich black smoke from the tail pipe on start up and while running. To check for this condition remove the vacuum line from the regulator, if fuel is present in the line the regulator has failed. Some GM (CPI Injection) are designed with an internal regulator that you must remove the upper intake manifold to inspect. Most fuel pressure regulators are on the fuel rail on top of the engine in plain sight. If you cannot locate your fuel pressure regulator consult a repair manual.

Removing the Vacuum Feed Line

Testing Fuel Pressure Regulator - The fuel pressure regulator adjusts fuel system pressure depending on the load of the engine. Vacuum is applied to the fuel pressure regulator to control system pressure. When the fuel pressure regulator is not functioning properly it causes the fuel pressure to be above normal operating pressure. This condition causes excess fuel to be injected into the engine causing a rich mixture that produces black smoke. To test for this condition (engine off) remove the protective cap and attach the fuel pressure gauge.

Attach Fuel Pressure Gauge

Support the fuel pressure gauge for observation, and then turn the key to the on position. The fuel pressure gauge should jump up to your system pressure. If you do not know your system fuel pressure consult a repair manual. Actual fuel pressure will vary slightly but should be fairly close to specification.

Fuel Pressure Gauge

Then, start the engine, the fuel system pressure should stay the same. While watching the gauge, snap the throttle, the fuel system pressure should jump up about 5 psi. If the system fuel pressure does not respond the fuel pressure regulator has failed. If the fuel pressure gauge falls the fuel filter is plugged or the fuel pump is failing. When testing is complete, remove the fuel pressure gauge feed line and replace the protective dust cap

Testing a Fuel Pressure Regulator

While an engine is running you should be able to hear the injectors clicking as the electronic valve opens and closes. To aid in this inspection use a stethoscope and touch it against each injector. If no audible sound is heard test fuel injector pulse and supply voltage output (this test is used for most cars). This test will tell you if the computer system has operating voltage and injector trigger signal. Remove an electrical connector from a fuel injector (all injectors need to be tested) probe both sides of the connector with a grounded test light or multimeter (voltmeter) (black lead) switched to DC voltage (there are only two terminals). Have a helper turn the key to the "on" position without cranking the engine and observe the test light.

The test light should illuminate one side of the connector only and the multimeter should be at about 12 volts. Next, switch the test light or multimeter (voltmeter) lead (black) or to the positive side of the battery to test the system ground injector trigger, probe the side of the connector that did not light up, have a helper crank the engine over and observe the test light, it should blink on and off or the multimeter (voltmeter) should bounce from 0 to 12 volts. (Note: if no injector pulse is present try disconnecting the remainder of injectors and re-test, if a fuel injector is shorted it can shut down the injector driver causing no injector pulse. If injector pulse returns plug the injectors electrical connectors in one at a time until the pulse fails and then replace that injector).

If this test revealed that there was no pulse but system has power, the PCM is not generating a fuel injector trigger. If there is no trigger to the fuel injector it will not allow fuel to enter into the engine. Some of the most common reasons that can cause this condition include a shorted fuel injector, injector wiring damage or shorted PCM. While the injector trigger wire is off, test the fuel injector windings by setting the multimeter (voltmeter) to ohms and attach the leads to either side of the injector. Your reading should be between 11 and 18 ohms. Test all of your injectors; if one injector reading is considerably different from the others replace that injector. Check the fuel pressure regulator, remove the vacuum line feeding the fuel pressure regulator, check for the presence of fuel, if fuel is present the diaphragm inside the regulator has ruptured and is feeding raw fuel into the engine causing it to run rough.

Fuel Injector

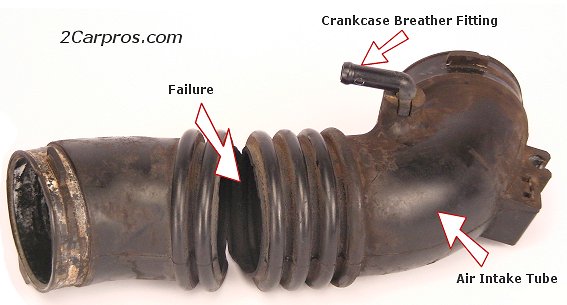

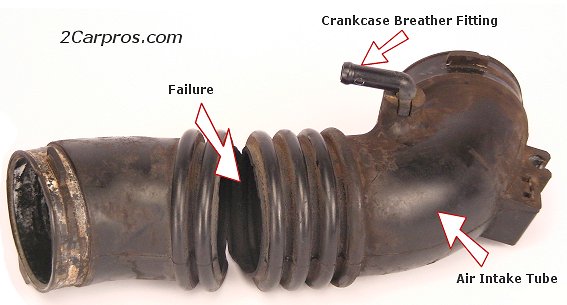

Check Air Intake Boot - An air intake boot is designed to transfer air from the mass air flow meter to the throttle bore. The PCM monitors this air flow and corrects fuel input. When an air intake boot fails it causes the PCM to respond by inputting more fuel than is necessary. This condition causes black smoke from the exhaust system. To check for this problem remove air intake boot to inspect for cracks or tears and replace if needed.

Torn Air Intake Boot

Check Engine Light - Service Engine Soon

If the check engine light is illuminated the PCM has detected a malfunction that could be causing the problem,scan the PCM to retrieve trouble codes and repair as needed.

Preventive Maintenance

To check your car's mixture you will need to use a gas analyzer to test your exhaust gases. This will measure the carbon monoxide, hydrocarbon, nitrogen oxide and oxygen content of your exhaust. During a normal smog inspection the fuel/air mixture is tested and a report generated. When a tune up is performed the spark plug end insulator can tell you whether you have a lean or rich mixture. Brownish grey is the desired color and confirms proper mixture. Black and sooty means the mixture is too rich while white to light grey confirms a lean mixture. Fuel injection systems rely on pressurized fuel to operate. Maintaining this pressure is mandatory for the system to function properly. Replace your fuel filter with every tune up to keep your injection system operating properly.

Maintenance

Maintenance for a vehicle is something that is often overlooked. From blank stares when asked when the last oil change occurred, to the even stranger looks that occur when asking when the last tire rotation was completed. It is very important to maintain oil changes and tune-ups that are performed on schedule. Proper maintenance to your car is a good way to keep all internal engine parts from becoming damaged prematurely. Without oil lubrication an engine will quickly become severely damaged. Anytime you are able to lengthen the life of the engine and help avoid breakdowns it is beneficial to the motoring experience.

Sometimes it is advisable to seek a professional ASE or other certified mechanic to trouble shoot the problem for the blue smoke condition. Never avoid engine problems as they can cause a simple and inexpensive repair to escalate to a costly repair that could have been avoided. Choosing the right mechanic or repair shop for your needs is often the biggest issue, however many times it can take just a referral from a friend or relative in order to find an appropriate repair shop. Poorly maintained engines are much more prone to problems such as smoking. The excessive friction leads to catastrophic engine failure. Preventative maintenance is cheap insurance to ensure that your vehicle runs as smooth as possible for many miles to come.

If further technical assistance is needed, our certified car repair technicians are ready to answer your car questions.

Related Car Repair Information

Black Smoke Engine Exhaust System

Check for Diagnostic Trouble Codes

Black smoke is caused by too much fuel being processed inside your car's engine and then released from the tailpipe of your car. Malfunctions in fuel delivery or internal system leaks will cause black smoke to come from the tailpipe. Before fuel injection became available in automobiles in the mid 1980's, the carburetor was the main fuel and air mixer in most vehicles. A carburetor was a simple device that supplied the engine with proper fuel to air mixtures. Carburetors performed two operations 1. meter air flow 2. deliver the correct amount of fuel to air mixture. This mix could be kept even during the wide range of extra factors associated with an engine such as high temperature, cold starting, hot starting, idling and acceleration.

The primary difference between a carburetor and a fuel injection system is that the fuel injection system atomizes fuel by pushing it through a small nozzle under pressure, while a carburetor utilizes vacuum created by air flow into the intake manifold. Airflow in an injection engine is controlled by the throttle body; fuel is distributed directly in each cylinder. This creates better fuel control, lower emissions and faster acceleration. The process of measuring the amount of fuel a fuel injector is dispersing is determined by the PCM (powertrain control module). The fuel injection system has several parts: the mass airflow sensor or map sensor, throttle body, throttle position sensor, idle control valve, fuel pump, fuel pressure regulator, fuel lines, and oxygen sensors.

Cause of Black Smoke

Black smoke is caused when the mix of fuel and air becomes un-balanced. Normal mixture is 14.5 parts air to1 part fuel. When the fuel to air mixtures change because of a malfunction the mixture can go as high as 14.5 to 2 or 3, two to three times the proper amount. The black smoke is the excess fuel generated from the rich mixture and can be cause by one of the following:

- Plugged Air Filter

- Shorted or stuck fuel injector

- Failed fuel pressure regulator

- Vacuum leak

- Shorted Computer Sensor

Troubleshooting Black Smoke for Exhaust

Testing for a Blown Fuel Pressure Regulator Diaphragm - A fuel pressure pressure by using a diaphragm/spring combination in conjunction with intake manifold vacuum. When the fuel pressure regulator diaphragm ruptures it allows raw fuel into the vacuum feed line and then into the intake system of the engine. This condition creates a rich black smoke from the tail pipe on start up and while running. To check for this condition remove the vacuum line from the regulator, if fuel is present in the line the regulator has failed. Some GM (CPI Injection) are designed with an internal regulator that you must remove the upper intake manifold to inspect. Most fuel pressure regulators are on the fuel rail on top of the engine in plain sight. If you cannot locate your fuel pressure regulator consult a repair manual.

Removing the Vacuum Feed Line

Testing Fuel Pressure Regulator - The fuel pressure regulator adjusts fuel system pressure depending on the load of the engine. Vacuum is applied to the fuel pressure regulator to control system pressure. When the fuel pressure regulator is not functioning properly it causes the fuel pressure to be above normal operating pressure. This condition causes excess fuel to be injected into the engine causing a rich mixture that produces black smoke. To test for this condition (engine off) remove the protective cap and attach the fuel pressure gauge.

Attach Fuel Pressure Gauge

Support the fuel pressure gauge for observation, and then turn the key to the on position. The fuel pressure gauge should jump up to your system pressure. If you do not know your system fuel pressure consult a repair manual. Actual fuel pressure will vary slightly but should be fairly close to specification.

Fuel Pressure Gauge

Then, start the engine, the fuel system pressure should stay the same. While watching the gauge, snap the throttle, the fuel system pressure should jump up about 5 psi. If the system fuel pressure does not respond the fuel pressure regulator has failed. If the fuel pressure gauge falls the fuel filter is plugged or the fuel pump is failing. When testing is complete, remove the fuel pressure gauge feed line and replace the protective dust cap

Testing a Fuel Pressure Regulator

While an engine is running you should be able to hear the injectors clicking as the electronic valve opens and closes. To aid in this inspection use a stethoscope and touch it against each injector. If no audible sound is heard test fuel injector pulse and supply voltage output (this test is used for most cars). This test will tell you if the computer system has operating voltage and injector trigger signal. Remove an electrical connector from a fuel injector (all injectors need to be tested) probe both sides of the connector with a grounded test light or multimeter (voltmeter) (black lead) switched to DC voltage (there are only two terminals). Have a helper turn the key to the "on" position without cranking the engine and observe the test light.

The test light should illuminate one side of the connector only and the multimeter should be at about 12 volts. Next, switch the test light or multimeter (voltmeter) lead (black) or to the positive side of the battery to test the system ground injector trigger, probe the side of the connector that did not light up, have a helper crank the engine over and observe the test light, it should blink on and off or the multimeter (voltmeter) should bounce from 0 to 12 volts. (Note: if no injector pulse is present try disconnecting the remainder of injectors and re-test, if a fuel injector is shorted it can shut down the injector driver causing no injector pulse. If injector pulse returns plug the injectors electrical connectors in one at a time until the pulse fails and then replace that injector).

If this test revealed that there was no pulse but system has power, the PCM is not generating a fuel injector trigger. If there is no trigger to the fuel injector it will not allow fuel to enter into the engine. Some of the most common reasons that can cause this condition include a shorted fuel injector, injector wiring damage or shorted PCM. While the injector trigger wire is off, test the fuel injector windings by setting the multimeter (voltmeter) to ohms and attach the leads to either side of the injector. Your reading should be between 11 and 18 ohms. Test all of your injectors; if one injector reading is considerably different from the others replace that injector. Check the fuel pressure regulator, remove the vacuum line feeding the fuel pressure regulator, check for the presence of fuel, if fuel is present the diaphragm inside the regulator has ruptured and is feeding raw fuel into the engine causing it to run rough.

Fuel Injector

Check Air Intake Boot - An air intake boot is designed to transfer air from the mass air flow meter to the throttle bore. The PCM monitors this air flow and corrects fuel input. When an air intake boot fails it causes the PCM to respond by inputting more fuel than is necessary. This condition causes black smoke from the exhaust system. To check for this problem remove air intake boot to inspect for cracks or tears and replace if needed.

Torn Air Intake Boot

Check Engine Light - Service Engine Soon

If the check engine light is illuminated the PCM has detected a malfunction that could be causing the problem,scan the PCM to retrieve trouble codes and repair as needed.

Preventive Maintenance

To check your car's mixture you will need to use a gas analyzer to test your exhaust gases. This will measure the carbon monoxide, hydrocarbon, nitrogen oxide and oxygen content of your exhaust. During a normal smog inspection the fuel/air mixture is tested and a report generated. When a tune up is performed the spark plug end insulator can tell you whether you have a lean or rich mixture. Brownish grey is the desired color and confirms proper mixture. Black and sooty means the mixture is too rich while white to light grey confirms a lean mixture. Fuel injection systems rely on pressurized fuel to operate. Maintaining this pressure is mandatory for the system to function properly. Replace your fuel filter with every tune up to keep your injection system operating properly.

Maintenance

Maintenance for a vehicle is something that is often overlooked. From blank stares when asked when the last oil change occurred, to the even stranger looks that occur when asking when the last tire rotation was completed. It is very important to maintain oil changes and tune-ups that are performed on schedule. Proper maintenance to your car is a good way to keep all internal engine parts from becoming damaged prematurely. Without oil lubrication an engine will quickly become severely damaged. Anytime you are able to lengthen the life of the engine and help avoid breakdowns it is beneficial to the motoring experience.

Sometimes it is advisable to seek a professional ASE or other certified mechanic to trouble shoot the problem for the blue smoke condition. Never avoid engine problems as they can cause a simple and inexpensive repair to escalate to a costly repair that could have been avoided. Choosing the right mechanic or repair shop for your needs is often the biggest issue, however many times it can take just a referral from a friend or relative in order to find an appropriate repair shop. Poorly maintained engines are much more prone to problems such as smoking. The excessive friction leads to catastrophic engine failure. Preventative maintenance is cheap insurance to ensure that your vehicle runs as smooth as possible for many miles to come.

If further technical assistance is needed, our certified car repair technicians are ready to answer your car questions.

Related Car Repair Information

No comments:

Post a Comment